The experimental results are consistent with the theory simulation ones. Therefore, the porosity of TC can be calculated by measuring the phase of the reflection coefficient.

Cst microwave studio evaluation software#

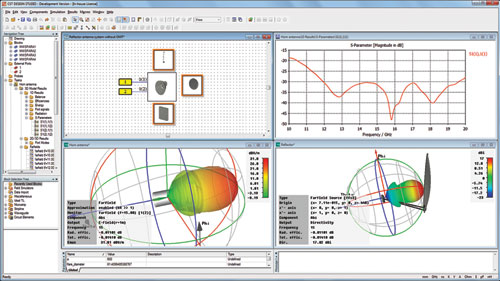

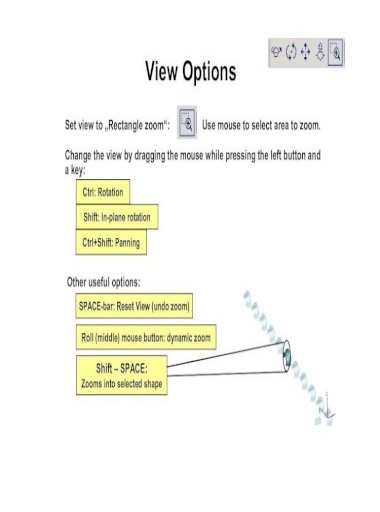

CST Studio Suite 3D EM simulation and analysis software CST Studio Suite is a high-performance 3D EM analysis software package for designing, analyzing and optimizing electromagnetic (EM) components and systems. The results showed that the phase difference increases linearly with increasing porosity of TC when the network analyzer operating over the frequency range of 30GHz to 40GHz. CST Studio Suite® electromagnetic field simulation software offers accurate and efficient computational solutions for electromagnetic designs. Besides, a network analyzer was used to measure the reflection coefficient phase which can be used in the evaluation of the TC porosity. Analysis of a reduced parameter set, that have an impact on the performance of small antennas with construction - / real estate - restrictions. Description of the task Following aspects are under investigation: 1. CST STUDIO SUITE substantially reduces completion times beyond the capabilities of many traditional workstation environments. And the sensitive frequency is different when TC thickness changes. CST Microwave Studio version 2019 with time domain solver is used for simulation and results. The results showed that the greater the porosity of the TC the larger the phase difference when the microwave was operated at the sensitive frequency.

The reflection coefficient at the interface of TC and waveguide probe was studied with regard to the TC porosity using computer simulation technology-microwave studio (CST-MWS).

Cst microwave studio evaluation code#

To ensure the quality of the TBCs, the evaluation of TC porosity was carried out using a microwave non destructive technique. T IME REVERSAL IN 3D CODE VERSUS TIME REVERSAL IN CST MWS (b) The aim of this study was to find out how exact antenna Fig. Porosity of top coating (TC) in thermal barrier coatings (TBCs) is one of the main factors affecting the thermal conductivity and causing failure of TBCs.

0 kommentar(er)

0 kommentar(er)